Incredible Four-Seat Comfort, Speed and Capacity.

The performance, handling and cost of the RV-10 make it the obvious choice in the limited field of four-seat kit airplanes, and a viable alternative to four-seat production airplanes – singles or twins – as well.

The RV-10 is a true four-person airplane, not just an airplane with four seats. It will carry four FAA standard adults, full fuel and sixty pounds of baggage while remaining at or below max gross weight. The cabin accommodates four full-sized adults. Both front and back seats will hold people 6’4″ tall and provide them with truly comfortable leg and headroom. Pilot seats can be adjusted in the cabin while seated. Composite gull-wing doors let the occupants board from both sides.

If your mission includes more than two people, and you like airplanes that perform and handle well, you really owe yourself a ride in an RV-10.

The RV-10 is designed to fly well on the bulletproof six-cylinder Lycoming O-540 engine, developing 260 hp. In our prototype, power is provided by a fuel-injected 260 hp Lycoming IO-540.

When many pilots say “performance” they really mean “speed.” The RV-10 is a fast airplane – it will cruise just under 200 mph – but speed is only part of the story.

The RV-10 derives its high cruise speed from a clean, light airframe instead of from a big, consumptive engine. This means cruise at lower speeds can be very economical. Company pilots often choose to cruise at 50-55% power and take advantage of the economy available there. At 175 mph, the RV-10 is covering more miles per gallon than most of the luxury cars, pickup trucks and SUVs it is flying over.

RVs are known for short-field capability and the RV-10 is no exception. Even at gross weight, the RV-10 can operate out of very short runways and climb well at high density altitudes. At the end of a flight, the generous wing area, big slotted flaps and robust steel rod landing gear allow the RV-10 to land at virtually any small airport — grass, gravel or pavement. If you can land closer to your destination, you can gain a lot of time over “faster” airplanes that must use big paved airports a long way from town.

Occupant protection is an important design criterion. The composite cabin top provides roll-over protection. Like all other RVs, the RV-10 has impressively low stall and landing speeds. If necessary, it can be safely landed in very small spaces at speeds that give the occupants the best possible chance of escaping injury.

The baggage compartment will accept 100 pounds of “stuff” loaded through the baggage door on the left side. If fewer than four people are traveling, the rear seatbacks may be removed in a couple of minutes for extra baggage space.

Up until the point at which the RV-10 was conceived, Van’s Aircraft was a two-seat aircraft company. Over time it became apparent there was a real market for a four-place RV. If we’re being honest, the decision to create the RV-10 was a big one, with some significant risk that represented stepping outside the then-current footprint of the business and into a new segment. The decision was made to invest the time and effort, and the company dove right in.

In the end, it worked out – and quite well.

With the mission of carrying four actual, real, grown adults and a full load of fuel, plus some baggage, the RV-10 was designed taking into account a number of things we’d learned from prior models. The metal portions of the kit were planned to be totally matched-hole, similar to the RV-7/9 kits we were already selling. We hoped to make the standard-build kits even easier to build, and of course we knew we would eventually offer RV-10 QB kits.

We also knew the wing would have to be a different design than we’d used previously. We’d had some recent experience with thicker-chord, high-lift wing designs in the RV-9/9A. Taking what we knew, a new airfoil was chosen to best meet the requirements we’d set forth while still ensuring we nailed Van’s signature “Total Performance” criteria. It had to perform like an RV, and it had to safely carry a real four-person load.

Ask any RV-10 owner or pilot and they will tell you, we hit that target.

If you were one of the folks who called Van’s at about 8:30 in the morning on May 29, 2003 and the phone rang and rang… Well, we had the best possible excuse. Most of the company was outside, standing along the taxiway watching Van taxi the brand-new RV-10 to runway 35. At about 8:40, the big six-cylinder spooled up (quietly, with that big muffler) and the airplane was in the air in about 450 feet. Takeoff and climbout certainly looked like an RV!

And the rest, as they say, is history.

Would you like to try our new online store?

- Flight Reports

- Builder Spotlight

- Designer’s Notebook

- Customer Service

- Reset Password

- Guidelines for Writers

- Advertise with Kitplanes

- Industry News

- Kneeboard Notes

- Homebuilder’s Portal

- Completions

- Build Series

- Aircraft Buyer’s Guide

- Buying a Used Homebuilt

- Unairworthy!

- Sign in / Join

- Free Newsletter

- Give a Gift

The Modern RV-10

A well-modded RV-10 points to the state of the art in homebuilt four-placers.

For Mark Easton, whose RV-10 you see on these pages, the answer was actually quite simple: He wanted a family airplane that was safe, one that he knew he could complete but also one that embodied some of the latest thinking in aviation. Technology was a driver for Easton, easily explained by his choice of automobile (a Tesla) but also his office. As in the right front seat of a Boeing 787 Dreamliner for American Airlines. It stands to reason, then, that Mark’s comfort with the latest in airliner tech would migrate to his Van’s RV-10 project.

Why We’re Here

Part of the reason for this exploration is to better understand how a stalwart design like the RV-10 can be modded to accept more modern technology than Van’s applied when it was first designed. Van’s penned the 10 quite conventionally, with the expected all-metal wing on the bottom, a “traditional” engine and sticks instead of yokes. About the only unusual thing for an RV—besides a six-cylinder engine up front—was the fiberglass shell that topped the cabin, a necessity as Van’s opted for doors rather than a large canopy. (Grumman AA-series owners love the visibility of the canopy, less so the chance of the interior becoming wet while getting in and out during a rainstorm.) Not to diminish the immense amount of work to create the RV-10, but it was, in the grand scheme of things, a carefully scaled-up version of what they were already familiar with.

Today, though, the opportunities to make an RV-10 your own are extensive. And knowing that our own Myron Nelson had an early (ish) RV-10 built largely to plans, I invited him to fly with Mark and compare notes, lodge a few large-scale impressions.

But let’s circle back for some context. Easton’s RV-10 is not so much a radical departure from the baseline aircraft, but more an expression of what has emerged in the ecosystem since Dick VanGrunsven first took flight in the RV-10 in May of 2003. When a particular model is popular, the aftermarket can invest in things like a custom cowling and have some assurance of a return on that investment. Easton’s airplane is a good sampler of the “good stuff” available for the RV-10 builder.

Our story starts forward of the firewall. According to Easton, “The modifications started when I decided that I wanted to use the FlyEFII system. I really didn’t want to put that on myself—it was my first airplane and my first build—and I knew that I could not get it from Lycoming under the Thunderbolt brand. So I called up Barrett Precision Engines , and Rhonda said, ‘Yeah, we can do that.’ I talked to Robert Paisley at FlyEFII, and he was on board to send the components to Barrett. That way, all the needed pieces would be built on the engine from the start.” By looping in a willing engine partner early in the process, Easton not only got assistance from Barrett but didn’t have to pay for items that he’d eventually have to strip off a “core” engine and resell.

Easton started with a narrow-deck IO-540 core that Barrett completely rebuilt with 9:1 compression and its usual menu of tricks to match internal components by weight for maximum smoothness. The choice of a narrow-deck engine was more a matter of what was available at the time, and while the so-called wide-deck configuration is current, the previous style is still supported.

“And then I found out that Barrett has a really good cool-air induction system, which I like for the extra performance. But then you had to do the Show Planes cowl to make room for that.” Show Planes, a Medford, Oregon, accessory maker and builder-assist center, had developed a round-inlet cowling system for the RV-10 that incorporated a cold-air induction system that cleverly uses the lower quarter of each inlet for the intake. The smile-shaped ducts feed down toward the throttle body, intersected by dual K&N reusable air filters; the system is configurable for use with either the Barrett cold-air system (itself an inlet plenum that sits proud of the oil pan to help keep the induction air cool) or a standard Lycoming forward-facing system.

Easton again, “And then, when I discovered that it was possible to split the Show Planes cowl down the middle, which makes it easier to remove, that’s when I decided to go with a three-blade prop.” In this sense, one mod begat the next mod, which enabled another decision, three big steps away from the more conventional RV cowling and FWF configuration that comes with the kit. It’s worth noting, too, that the Show Planes cowling uses a larger spinner, but that was available from Whirl Wind Aviation, whose three-blade composite prop sits at the pointy end of the RV. Easton also went with Skybolt quick-turn fasteners for the cowling instead of the more common hidden piano hinge. “With the split lower cowling, I can remove the entire cowl by myself in 5 minutes. And, just as important, put it back on by myself.” Easton also says that this configuration helps with maintenance decisions. “I know that with the cowling being easier to remove, I’m more likely to check something I’m curious about.”

“In the end, did I need to do any of it?” Easton asks. “The cold-air induction costs money. The three-blade prop is more expensive. Could I have been happy without all of that? Sure. But it just kind of worked its way through the project.” Veteran builders know this mission creep well, but Easton tried to let the process guide itself rather than simply throw the latest and greatest at the airplane.

Avionics Ascendant

The same discussion of incremental cost informed the panel layout. Centered on Advanced Flight Systems EFISes, the panel is comprehensive and suitably redundant. “We decided to add the third screen, and that added $4200 or so to the project. But I was talking to my wife about it, and she pointed out that we’ll probably get some part of that back should we decide to sell but, more important, let’s build it the way we want to fly it.” In the typical configuration, the pilot’s screen is the primary flight display with the engine instruments along the lower edge. The large central screen is the multifunction display for moving map and weather, with the right side display configurable as either a PFD or MFD, depending on the needs of the copilot. (Mark’s wife, Caroline, is a 737 pilot for United, so a right-side PFD will be handy when she boots Mark over there.)

Electrics FWF

You appreciate how important a stable, redundant electrical system is when you think more about the FlyEFII System32 digital ignition and fuel-injection system. Simply put, without electrical power, the engine doesn’t run. Developed by Robert Paisley, the system is sophisticated by light-aircraft terms, but it’s actually fairly simple among car and motorcycle systems. At its heart, the System32 has a pair of redundant Engine Control Units (ECUs) that monitor several variables: crank position, throttle position, manifold pressure, induction air temperature and fuel pressure. The ECUs take each sensor’s readings, compare them to stored maps, then calculate both the ignition timing and the fuel mixture.

Like the most common electronic fuel injection systems, injectors mounted at the induction tube on each cylinder—the top injector hole is unused—meter fuel to each cylinder. The amount of fuel they disperse depends on inlet fuel pressure and the amount of time the injector solenoid is held open, also known as dwell time or duty cycle. Because each injector is controlled individually, it’s possible to trim each cylinder’s fuel delivery so that all six have a small “GAMI spread,” or the offset in fuel flow from the first cylinder to reach peak EGT and the last, when the overall mixture is leaned. A small spread means the engine runs more smoothly at lean-of-peak (LOP) fuel mixture.

The FlyEFII system includes coil packs to provide spark at each cylinder and runs automotive plugs; the pickoff point is a set of sensors on the starter ring gear, not at the magneto drive. (Which is subject to gear lash.) In Easton’s airplane, the coil packs are above and behind the engine, mounted to the engine mount.

Of course, since System32 uses electronic fuel injection, the traditional Lycoming diaphragm pump is replaced by dual electric pumps. The system is “full return,” meaning that fuel is drawn from one of the RV-10’s tanks, circulated through the fuel pumps, lines and presented to the injectors; what’s not consumed is returned to the selected tank. Full-return systems are less prone to vapor lock than “one-way” setups, but they impose greater burdens on design and plumbing. In the grand scheme of the additional complications on Mark’s RV-10, this was not a huge new one.

The core benefits of the FlyEFII system are better-controlled fuel mixture, no need to manage the mixture knob in flight (though there is an exception) and an ignition system that can advance timing to improve efficiency. And since the fuel system is always under pressure, engine starts (cold and, especially, hot) are no-hassle affairs. The FlyEFII system can also send a data stream to the engine monitor to display fuel flow, though the dedicated System32 control head also shows fuel flow. For more on how this RV-10 flies, see “Flying the Electrons,” below.

Easton spent a ton of time on the FWF and avionics, but he also splurged on the interior. Four leather seats from Aerosport Products, plus a custom center console, interior panels and other details give this RV-10 the finished feel of a modern Cirrus. Full Crow harnesses keep the passengers in place. The interior is amazingly quiet, too.

It wouldn’t be unreasonable to ask about Easton’s investment here, and his response is a number smaller than you’d think. “I’d say I have around $225,000 into the RV,” he says, noting that he saved a lot of money by starting with a “slow-build” kit, performing some avionics and much integration work on his own and farming out only what he didn’t have the expertise or tools to accomplish. Perhaps a positive side effect of his day job—time off—Easton was able to complete his RV-10 in five years. In fact, his first flight came five years and a day from the start of the project, which was built in a four-car garage in his home near Portland, Oregon.

Mark’s RV-10, like so many, is still not 100% done, though he’s already had a few vacation days traveling with the family. He’d like to continue refining the cooling system; there’s some electrical noise to ferret out, among other small items. But he’s happy with his decisions. For the most part, the gamble on the FWF technology has paid off. This RV-10 is as simple to operate as it can be yet provides excellent performance along with the versatility and fine flying qualities that made the RV-10 a success in the first place.

RELATED ARTICLES MORE FROM AUTHOR

A Baker’s Dozen

The Jet A- Burning RV-9A

Van’s Aircraft Year-End Update: “Significant Strides”

Second Chance Six

Van’s RV-15 Prototype Gets a New Tail

Ten For Ten: A Decade With an RV-10

Weighing an RV-10

The Snazzier 10

Happy To Be Here Club Meets at Van’s AirVenture Banquet

Leave a reply cancel reply.

Save my name, email, and website in this browser for the next time I comment.

This site uses Akismet to reduce spam. Learn how your comment data is processed .

In Case You Missed It

Perking up the performance of a Glasair Sportsman

A Witch’s Brew

Vacuum Bagging for Homebuilders

Remember When: The BD-5 Micro

- Privacy Policy

- Terms of Use

Hands, Mind, and Heart

- Aircraft Building

- Kits & Plans

Low wing - All Metal - Fixed Tricycle Gear

Recent articles.

Articles in EAA and related publications:

EAA members can view digitally archived editions of EAA Sport Aviation here .

10 Prominent Experimental Aircraft Developed By Van's Aircraft

V an's Aircraft, founded by Richard VanGrunsven in 1973, has significantly influenced the experimental aviation sector with its RV product series. These aircraft, known for their performance and versatility, have become a staple among homebuilders and pilots. We'll explore some of the most prominent experimental aircraft developed by Van's Aircraft.

RV-3: The original single-seater

A first in a time of homebuilt aircraft popularity.

The RV-3, introduced in 1972, was VanGrunsven's first design. This single-seat, low-wing monoplane set the foundation for the RV series. Its all-aluminum construction and emphasis on performance made it a favorite among solo pilots seeking aerobatic capabilities. Its kit price of $2,995 contributed to its popularity. The RV-3's success demonstrated the potential for high-performance homebuilt Aircraft, leading to the development of subsequent models.

RV-4: Tandem seating and enhanced performance

Van's move to create a two-person homebuilt kit.

Building upon the RV-3, the RV-4 introduced tandem seating, allowing for two occupants. This configuration maintained the RV-4's aerobatic prowess while accommodating a passenger.

The RV-4 design improvements included a bubble canopy and enhanced aerodynamics, contributing to its popularity among builders and pilots. Its success paved the way for future two-seat models in the Van's RV lineup.

Yes, there was an RV-5, and it was a one-off proof-of-concept prototype. Richard VanGrunsven created the RV-5 as a project for members of his EAA chapter, and it was never intended for production. The Van's RV-5 was designed in 1975 and first flew in the summer of 1976 - the design explored performance with very low fuel consumption in light of the 1970s energy crisis.

RV-6/6A: Side-by-side seating

Popular rv 6 provided side-by-side seating and greater versatility.

The RV-6, launched in 1986, marked a significant evolution with its side-by-side seating arrangement. This design choice improved pilot-passenger interaction and broadened the plane's appeal.

The RV-6A variant featured tricycle landing gear, catering to pilots preferring nosewheel configurations. With over 2,600 units completed, the RV-6/6A became one of the most popular kit aircraft ever produced.

Unique Way To Fly: 4 Popular Kit Aircraft

Trainee pilots generally learn to fly in such aircraft.

RV-7/7A: Modernization and enhanced aerobatics

Rv7 and 7a further refine the design and performance.

The RV-7 and its tricycle gear counterpart, the RV-7A, replaced the RV-6 series and offered modernized features and improved performance. Introduced in 2001, these models incorporated a longer wingspan and larger rudder, enhancing aerobatic capabilities.

The RV-7/7A's roomy cockpit and side-by-side seating continued to attract pilots seeking a versatile and high-performing aircraft.

RV-8/8A: More modern enhancements

More tandem seating and a bigger cabin.

The RV-8 series revisited the tandem seating configuration, offering a modern take on the RV-4's design.

With a broader fuselage and increased cockpit space, the RV-8/8A comfortably accommodates larger pilots. Its aerobatic capabilities and excellent visibility make it a favorite among sport pilots. The RV-8A variant provides a tricycle landing gear option, catering to different pilot preferences.

RV-9/9A: Focus on efficiency and training

The van's rv was purpose-built for cross-country flying and flight training.

The RV-9 series, introduced in the early 2000s, emphasized efficiency and docile handling characteristics. Designed for cross-country flying and flight training, the RV-9/9A features a larger wing and is optimized for lower horsepower engines.

Its non-aerobatic design appeals to pilots seeking a stable and economical aircraft for travel and instruction.

RV-10: Expanding to four seats

The RV-10, Van's first four-seat Aircraft, expanded the RV series into family and group flying. Introduced in 2003, it offers a spacious cabin and impressive performance, cruising at just under 200 mph.

The RV-10's design accommodates a 260 hp Lycoming engine, providing ample power for its size. Its popularity among builders underscores the demand for high-performance, homebuilt four-seat Aircraft.

RV-12/12iS: Embracing light sport aircraft

Van's entry into the lsa market.

The RV-12 series marked Van's entry into the Light Sport Aircraft (LSA) category.

With removable wings and a focus on ease of construction, the RV-12 appeals to builders seeking a straightforward project. The RV-12iS variant, introduced in 2017, features a fuel-injected Rotax engine and other enhancements, offering improved performance and efficiency. Compliance with LSA standards makes it accessible to a broader range of pilots.

RV-14/14A: Roomier Cockpit and Advanced Features

The RV-14 series, unveiled in 2012, offers a larger cockpit and advanced features, catering to pilots seeking comfort without sacrificing performance.

Designed to accommodate the Lycoming IO-390 engine, the RV-14/14A provides impressive speed and climb rates. Its design includes pre-punched holes and other builder-friendly features, streamlining the construction process. The RV-14A variant offers a tricycle landing gear option.

RV-15: Van's First High-Wing Design

The RV-15 is a departure from Van's traditional low-wing designs, introducing a high-wing, back-country-capable aircraft. First publicly shown at AirVenture in July 2022, the RV-15 offers short takeoff and landing (STOL) capabilities, appealing to pilots interested in off-airport operations.

As of July 2022, the company was not yet accepting deposits for delivery positions, suggesting that the RV-15 is still under development.

Van's Aircraft Legacy of Innovation

Van's Aircraft has continually evolved its designs to meet the diverse needs of the aviation community. From the single-seat RV-3 to the high-wing RV-15, each model reflects a commitment to performance, versatility, and builder support.

US test flight of an RV10 aircraft with the TP100 engine

Sign up for our newsletter, meet our new colleagues, discover what's new at pbs aerospace, new customer support hub.

FlightLog Archive

Aircraft flown, flying the rv-10 - oct 2018.

I have really enjoyed flying various models of Van's Aircraft homebuilt experimental aircraft, and have been lucky enough to check out the RV-6 , RV-7 , RV-8 and RV-12 in-flight over the past few years. All the RV series aircraft have very responsive flight controls, crisp aileron response, great visibility, and are just a joy to fly. After flying many of the two-seaters, I wanted to fly the RV-10 and check out the feel of Van's larger four-seater.

A few years ago, my friend and fellow Air Force Academy grad, Stan Mars, mentioned that another classmate of ours, James Ruttler, had a son who was building an RV-10 at Bremerton. I followed Jim's progress on his blog , noting that he completed his RV-10 and had a successful first flight in March 2016. Jim later finished his RV-10 with a stunning paint job, and I had seen his aircraft a few times while flying in and out of Bremerton.

Early in 2018, I volunteered to beta-test an innovative CO detector, named Aithre , which Jim Ruttler was developing. I was able to test fly two versions of the Aithre units throughout the summer of 2018 in many different aircraft. I noted that Jim was doing a lot of testing in his RV-10, and tried to coordinate our schedules for a demonstration flight. Just as the beta testing was completed, I happened to fly to Bremerton for a halibut run to the Airport Diner, and saw Jim land and taxi in with his beautiful RV-10. We arranged for a flight attempt in the coming weekend, plus an Aithre beta unit return.

I flew over from Renton in my Warrior on Saturday, on a clear afternoon with strong northerly winds and quite a bit of low-level turbulence. Shortly after I arrived, Jim taxied in with his RV-10, after flying with another local pilot. Jim's RV-10 has a striking blue paint job with white accent lines, plus recently added nose art depicting Aithre, the Greek 'goddess of sight and of bright blue skies'.

Entry into the RV-10 is easy with the huge gull-wing doors. Jim thought they were one of the weak links in the design, with alignment and closing issues, but Jim's seemed to work well. The RV-10 cockpit is quite spacious, with good shoulder room and nice headroom, even for my tall sitting height. Jim's panel was nicely equipped with two large Advanced Flight Systems displays, with ADS-B in/out and a coupled autopilot system. My favorite part was that the RV-10 was equipped with two sticks and a central throttle quadrant. I much prefer a stick over a yoke, and the layout felt right at home from the right seat.

Jim started the IO-540 effortlessly, and we taxied to the active after a run-up and systems check, using the checklists available on the displays. The IO-540 provided nice acceleration on takeoff, and we climbed steeply into the strong northerly winds with our light load. Jim let me takeover and get a feel for the flight controls. While they felt a bit heavier than the two-seat RVs I have flown, the -10 still had that RV crispness, especially in roll. Jim installed a trim system control on his stick, which allowed for easy trim off of stick forces in the climb and descent.

Visibility was great, and I got a good feel for the aircraft while flying patterns at three different local airports - Tacoma Narrows, Olympia and Shelton. The RV-10 on go-around needed a bit more forward stick than I initially anticipated in the climb-out. The power of the IO-540 while departing these three airports at near sea level was impressive.

My overall impression from this short 1.2 hour flight is easily summarized: I want one! The RV-10 flies well, climbs well, has great visibility and cockpit controls, has an intuitive and capable IFR suite, and in Jim Ruttler's example, has a gorgeous interior and exterior.

Jim, thanks for the demonstration flight. We now just need to schedule a formation photo shoot in the spring to get you in the Van's Aircraft calendar!

In November 2018, I was able to fly a close competitor to the RV-10, the Sling TSi , produced by the Airplane Factory from South Africa. The Sling TSi, with the new Rotax turbocharged 915iS engine, is an impressive offering, and gives the RV-10 a worthy competitor if you are searching for an outstanding homebuilt 4-place touring aircraft. Decisions, decisions...

Chris Lucas’ RV-10

David gustafson.

Chris Lucas’ RV-10

There have been over 500 designs for homebuilt aircraft over the past six decades, the majority being for single- and two-place aircraft. It’s unlikely that there have been 15 four-seat designs, and not many have enjoyed any kind of success as kits. Very few have shown up at Oshkosh. Of those in production, the RV-10 stands out as one of the fastest, most economical (to build and operate), and though it’s a subjective call, it may be the most pleasing to look at. Being a four-place, it requires a longer build time and costs more than most two-place kits (but not all).

Chris Lucas recently finished his RV-10 project, has logged 13 hours in it and is thrilled with the outcome. He enjoyed the building so much that he’s thinking of building another tail section just for the fun of it (he’d sell it when completed). Between the day he first saw the RV-10 at Oshkosh 2003, which prompted him to write out a check for serial number 72, and his first flight on Nov. 27, 2011, a little over 8 years elapsed.

Chris grew up with an admiration for all things “aviation”. He built models, earned his private in college, where he got a degree in aerospace engineering, hired on with the Navy and later entered a partnership on a C-35 Bonanza. That worked well until he took it in for an annual by some people he didn’t know. The whopping price of that annual got him thinking about finally building his own airplane. He had been fascinated by Burt Rutan’s creations with composites and really liked the performance of the Lancairs, but the price of the kits kept shooting up which put him off. For a while he focused on the Murphy Super Rebel. In the end, cost, performance and a growing family drove him to select the RV-10.

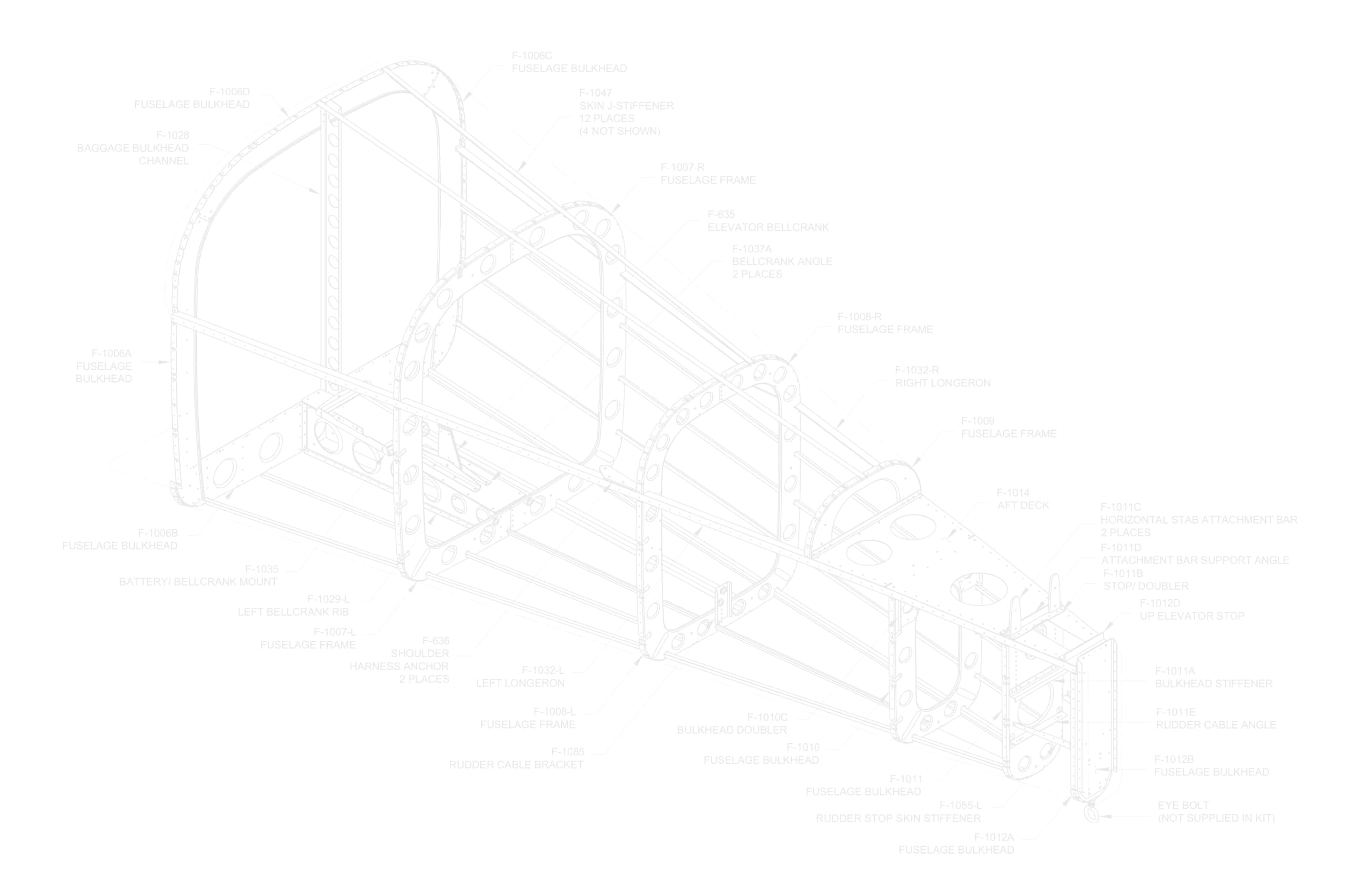

Chris has a two-car garage that became his workshop. With help from his wife, whom he identifies as “the Enabler”, his father Robert, and friends Bill Hood and Robert Montidonica, CFI, A&P, IA, he made steady progress. As Vans Aircraft has done repeatedly, there were a total of five kits. The first, a tail kit, included everything from the baggage compartment aft. That section took Chris about a year to complete. Several months later the wing kit arrived and he tackled the spars, ribs and covering material (all aluminum). The third kit was for the cabin. The fourth consisted of engine mount, gear and cowlings. The final included the engine and prop.

The doors and cabin top are made out of composites which gave Chris the greatest challenge. Getting everything to fit flush and line up properly along with installing the windows took considerable time and effort. He was much happier working with the aluminum components.

They were pre-aligned. The holes for rivets had been punched for the ribs and skins at the factory. He simply had to enlarge the holes, debur them, insert clecos, and then begin replacing the clecos with rivets. There was very little fabrication; most of it having been done at the factory, and the instructions/plans, according to Chris were like an RC model, with step by step, check-it-off instructions and three view drawings to assist. He estimates that he made no more than 10 phone calls to the factory for builder assistance.

Though he fretted and worried about the wiring, after some reading, online chats and discussions with friends, it turned out to be one of his most satisfying experiences.

Chris made two changes to the design. They’re minor enough that he likely won’t incur the wrath of the factory, which disdains mods of any kind. The first was a compromise with the mean temperatures at his home in New Bern, North Carolina. He mounted a ceiling panel with lights and created an air vent, using a Bonanza part. He also did away with the piano hinge that was to be mounted on the outside for the baggage door, substituting hidden hinges.

On the day of his first flight, “I was super nervous.” A couple months prior, Chris had gone out to Oregon to log 9 hours of transition training in the factory’s RV-10. That experience allowed him to keep his cool. As he lifted off, the fear vanished. “Landings are non-events. With the break-in for the engine I’ve been running it at 24-squared and I’m getting 165 knots in cruise.” He has a Lycoming IO-540D4A5, 260hp in the front office. His panel is mainly Grand Rapids Technology EFIS and Garmin products.

“The project was a good idea and I’m glad I did it. It feels funny to be an airplane owner again…sometimes it feels surreal.”

View our photo gallery of Chris Lucas' RV-10.

For more articles like these, visit www.aircraftspruce.com/catalog/kitspages/perspectivesonHB.php .

Sign-up for newsletters & special offers!

Get the latest FLYING stories & special offers delivered directly to your inbox

IMAGES

COMMENTS

The RV-10 is designed to fly well on the bulletproof six-cylinder Lycoming O-540 engine, developing 260 hp. In our prototype, power is provided by a fuel-injected 260 hp Lycoming IO-540. When many pilots say “performance” they really mean “speed.”

Construction of an RV-10 wing in a garage An RV-10 at the Van's Aircraft display at Sun n Fun 2006 in Lakeland Florida RV10 at EAA Airventure 2014 RV-10 landing. The Van's Aircraft RV-10 is a four-seat, single-engine, low-wing homebuilt airplane sold in kit form by Van's Aircraft.It is the first four-seat airplane in the popular RV series. [3] The RV-10 first flew on 29 May 2003, and the first ...

Apr 15, 2015 · Flying—one glance lets you know that this is no ordinary RV-10. Turbine Solutions Group’s concept demonstrator is a full 10 inches longer than an IO-540 piston-powered RV-10. The stretch was necessary to keep the airplane in CG with the lightweight TP 100 turboprop engine out front.

Sep 20, 2024 · It’s powered by a Barrett Precision Engines IO-540 built to Lycoming D4A5 specs—the spec Van’s recommends—and a Hartzell “blended airfoil” two-blade aluminum propeller. Routine consumables over the last decade include the following: six Monster retread tires, four mains and two noses. Three sets of brake pads (standard Van’s/Cleveland).

Sep 30, 2021 · This RV-10’s cockpit centers on Advanced Flight Systems screens with a smattering of remote boxes for com and transponder. The rest of the avionics are made up of an Avidyne IFD 540 com/nav/GPS, backed up by a Dynon remote com, Dynon integrated autopilot and a Garmin G5 backup instrument.

What started as a handful of passionate enthusiasts has developed into a major force—and a significant component—of the aircraft industry. EAA members can view digitally archived editions of EAA Sport Aviation here.

The RV-10, Van's first four-seat Aircraft, expanded the RV series into family and group flying. Introduced in 2003, it offers a spacious cabin and impressive performance, cruising at just...

Jul 2, 2014 · The TP 100 engine powered a 4-seat RV-10 in the experimental category. The success of the flight represents an important step in bringing this new engine closer to final certification and to the gradual launch of its serial production.

The RV-10 flies well, climbs well, has great visibility and cockpit controls, has an intuitive and capable IFR suite, and in Jim Ruttler's example, has a gorgeous interior and exterior. Jim, thanks for the demonstration flight.

Jul 31, 2012 · Of those in production, the RV-10 stands out as one of the fastest, most economical (to build and operate), and though it’s a subjective call, it may be the most pleasing to look at. Being a...